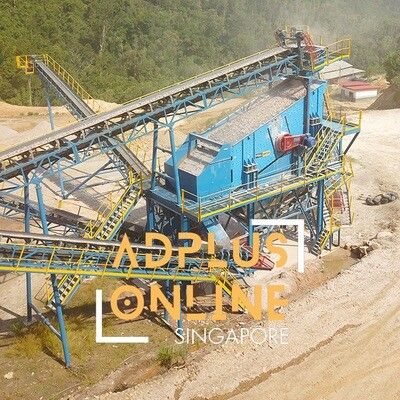

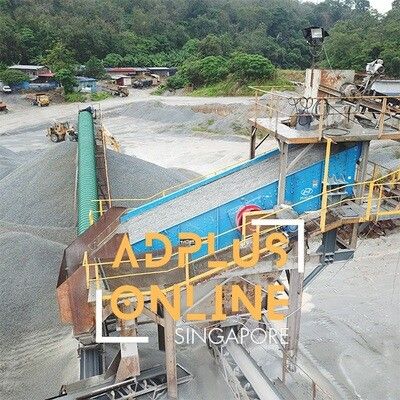

ADplus 1512 Vibrating Screen with 5.5kW Electrical Motor

ADplus 1512 Vibrating Screen with 5.5kW Electrical Motor

Product Information

SIZE 1524mm x 3660mm x 1 Deck

MOTOR POWER 5.5 kW

NO. OF POLES 4

VOLTAGE 380 - 415V

FREQUENCY 50 Hz

SPEED 1,500 rpm

NOTE Excludes any screening media

Product Features

INNOVATIVE CENTRIFUGAL COUNTER WEIGHT ASSEMBLY

This innovative feature eliminates excessive resonance motion when the screen is starting or stopping. At start-up, the counter weight assemblies have a small “mass x radius” value. This means that they accelerate to operating speeds with a smaller driving torque and drive motor than for a conventional vibrating screen with fixed counter weight.

SCREEN DRIVE

The driving pulley may be fitted to either side without disturbing the shaft. This means that the drive can be positioned to suit the installation. Depending on the screen size, two or four ‘C’ section v-belts are required for the drive.

GUARDS

There are fully enclosed steel plate guards over the counter weight assemblies. They are easily removable to allow inspection or maintenance of the counter weights or mechanism.

SCREEN BODY

Structural strength of the screen body is enhanced by bending the entire top length of the screen body. This crucial features prevents horizontal warping of the screen side plates. Enabling this well-reinforced screen body to have long life without additional weight. Vertical stiffening angle irons add additional rigidity to the side plates.

RUBBER BUFFER STRIPS

Self-clamping, wear resistant rubber buffer strips are fitted to the screen frame mesh supports and prevent metal-to-metal contact. This cushioning increase screening media wear life.

FEED BOX & DISCHARGE SPOUTS

FLEXIBLE BACK PLATE COVER

Every ADPLUS vibrating screen is fitted with a flexible rubber back plate cover above each deck. This allows inspection and removal of the screening media.

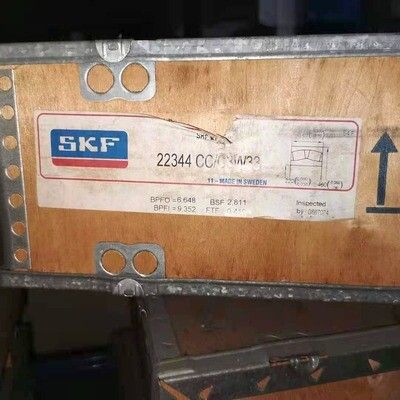

RELIABLE FAG BEARINGS

The FAG self-aligning, double row, spherical roller bearings were developed specifically for vibrating screens. To eliminate locking of the bearing to the shaft (which leads to premature failure), the inner rings of the bearings have self-lubricating sleeves. The bearings are protected from dust and dirt by grease-purged labyrinth seals. Grease lubrication is standard for all ADPLUS vibrating screens.

SELF-ENCLOSED BEARING CARTRIDGE

The load-carrying roller bearings in the vibrating mechanism, together with their mounting cartridges and cover, can be assembled in the dust-free atmosphere of a workshop and fitted to the screen in the field as a complete unit. This means the bearings are not exposed to dust particles during assembly and can be relied on for their rated lifetime.

Delivery Time