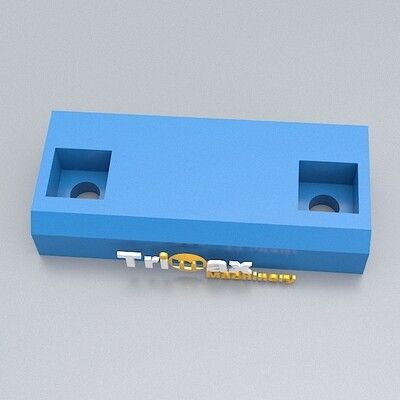

Challenger CMC 116L Jaw Crusher

USD 1 599 998.40

Delivery Location

Payment

Pre-Order

In stock

Save this product for later

Challenger CMC 116L Jaw Crusher

Product Details

Weight: 54 100.00 kg

Product Information

- Supplied with feed hopper with volume of 4.8m3.

- Supplied with 1 unit x 1,100mm x 4,000mm grizzly feeder with 1 unit x 15kW electrical motor.

- Supplied with grizzly bars of 50mm gap on the grizzly feeder.

- Supplied with JC106 jaw crusher with 1 unit x 110kW electrical motor.

- Supplied with overband magnet 1,000mm.

- Supplied with Weichai 300kW engine.

- Supplied with main discharge conveyor of 1,000mm width.

- Supplied with side conveyor of 650mm width.

- Equipped with Smart Diesel-Electric capability for direct connection to government supplied electrical grid (if required) or external diesel generator (if required).

- Equipped with Intelligent PLC Automated Control System for easy operations, real-time monitoring and control.

- Equipped with portable wireless controller for ease and convenience.

- Fitted with discharge conveyors that can folded hydraulically for convenient transportation.

- Capacity: 350TPH @ CSS 150mm

- Hopper Feed Height: 4,103 mm

- Machine Weight: 57,500 kg

- External Dimensions : 16,929 mm x 4,630 mm x 4,539 mm

- Transport Dimensions : 14,500 mm x 3,050 mm x 3,780 mm

Product Features

SMART DIESEL-ELECTRIC DRIVE

Besides a high performance and powerful Weichai diesel engine onboard electrically driving the crushers and conveyors, CMC Mobile Crushing & Screening Plants are able to be connected to the government supplied electrical grid. This flexibility results in a highly reliable, operationally economical, and environmentally conscious crushing & screening operation.

LARGE FEED HOPPER

Maximised productivity and trouble-free feeding thanks to the high-capacity feed hopper. In addition, in some models, the hopper volume may be optionally increased by hydraulically extending the hopper walls.

SELF-CLEANING OVERBAND MAGNET

Installed as standard preventive safety equipment in all Trimax Challenger CMC Mobile Jaw Crushers and Horizontal Shaft Impactors to effectively remove unwanted tramp iron from the main discharge conveyor, the self-cleaning overband magnet ensures uninterrupted optimal production of the entire crushing line.

INTELLIGENT PLC WITH WIRELESS REMOTE CONTROL

There are fully enclosed steel plate guards over the counter weight assemblies. They are easily removable to allow inspection or maintenance of the counter weights or mechanism.

SCREEN BODY

A simple yet intuitive PLC system guarantees the user optimal control over the initial set-up once the plant arrives on site and during subsequent operation, even via a wireless remote control.

ROBUST STRUCTURAL STEEL CHASSIS

A strong yet compact steel chassis is crucial for the plant to withstand all the tough load-bearing pressures it expects to encounter during normal operations.

HEAVY DUTY TRACKS

Reliable heavy duty tracks that offer superior grip in muddy conditions enable stability and flexible mobility within the site.

Delivery Time

In order to provide you with the most economical prices, the Trimax Online Indonesia prices are based on consolidated bulk shipping whenever possible. Shipping is typically initiated within 3 to 4 months. Depending on your shipping address, please allow additional days in transit for delivery. If you require expedited shipping, please indicate this urgency to telysa@trimaxmachinery.com after you have completed your order and received your order confirmation email. Depending on stock availability, we may be able to accede to your request. You will be advised of additional shipping charges associated with expedited orders and have the option to either proceed or cancel the order.

You May Also Like

Display prices in:USD